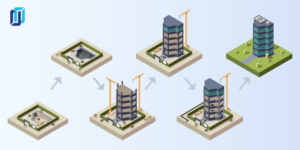

When it comes to a construction project, nothing happens overnight. There are a lot of moving parts, and every job requires meticulous planning and oversight. But rather than deal with the project as one big undertaking, it’s more manageable to break it down into segments or construction phases.

There are six critical stages of construction: pre-construction, sitework, rough framing, exterior construction, MEP (mechanical, electrical, and plumbing), and finishing. Some stakeholders consider the stages of construction in terms of pre-construction (bidding, plans, specifications, and drawings), construction (including all aspects of building), and post-construction (project close-out, punch lists, and occupancy). In any case, breaking a construction project down into stages is essential for managing the complexity involved with so many people, materials, plans, and more.

We’ll cover all of the major stages in this article, so read on for a detailed look at what it takes to move a construction project from beginning to end.

The 6 stages of construction

Projects can’t just happen at once. They need planning, orchestration, and a lot of knowledgeable people to make them happen. For that reason, projects are broken up into construction phases, each with different types of contractors and risks involved. The following are six construction phases that most sites go through, from drawings to completion.

1. Pre-construction

The pre-construction phase is the point where someone takes an idea and puts it into motion. This stage involves planning, surveying, engineering, design development, permits, and more. It serves as the roadmap the rest of the project will follow.

The pre-construction phase involves a number of parties, which may include:

- The property owner

- An architect or architecture firm

- Engineers

- A general contractor

the general contractor taking the job, the architect or design professional, an engineering firm, a surveyor, and anyone else who might need to approve the site or plans. This is also when a general contractor will start the procurement process in their search for subcontractors.

Since the project hasn’t actually broken ground yet, financial risk to the companies involved in the preconstruction phase can actually be significant. Slow payments are a common occurrence on all phases of a construction project. While a mechanics lien is the most effective way to ensure payment, parties performing work at this stage may not have lien rights. It depends largely on the state laws where the property is located.

Check out this map to see where design and other preconstruction services are backed by lien laws.

2. Sitework and foundation

The second stage of construction is when the project finally breaks ground. Crews get the site ready by grading the property, digging or drilling for a foundation and footings, and developing a driveway for deliveries and subs. They’ll also drill wells and bring underground utilities to the site, like electricity and gas.

The general contractor, architect, engineer, and surveyor are all still involved at this stage, but different types of subcontractors also enter the mix. The excavation, earthwork, drilling, utilities, concrete, framing, and scaffolding subs are usually on-site and working together to get the concrete poured and the foundation ready for vertical building.

Phase risks

GCs and subs have several risks to worry about during the sitework and foundation phase. First, they’re often dealing with retainage, which often means a chunk of their cash is being withheld until the end of the project. On a large-scale commercial job, contractors may be waiting a year or more to collect retained funds, which are typically 5-10% of their overall contract price. Retainage can take an enormous toll on a contractor’s cash flow.

They also need to worry about site conditions not jiving with the drawings, as well as weather delays disturbing the timeline. Finally, everyone on the job has to worry about the project owner or GC’s financial stability, as bankruptcy can bring the job to a halt, and along with it, their payments.

3. Rough framing

The third of the sixth phases of construction is rough framing, and it’s when the building starts going vertical. The cranes lift the structural steel into place while steel contractors attach it to the foundation and footings.

With the steel for each floor in place, crews pour the concrete for the floors. After that, the framing sub will build the walls and give the building its main structure.

This phase is a big undertaking, but it usually involves fewer subcontractors. As always, the general contractor is on-site, along with the scaffolding sub, the framing sub, and the structural steel and metal subs. A lot of this stage involves cranes, welding, and metal framing.

Phase risks

Since the building is still open to the elements, weather delays are still a big concern at the third stage. Also, the fear of bankruptcy doesn’t fade until the job wraps up and the checks clear the bank. Retainage is also still an issue, but with the volatility of materials pricing (another risk), it can really crush a subcontractor’s cash flow.

4. Exterior construction

The fourth phase of construction involves “drying in” the building, or sealing it off to the elements. This stage involves installing the windows, doors, siding, roofing, any brick or plasterwork, and everything else the drawings call for on the exterior of the building.

The subcontractors on-site start looking a bit different at this stage. The general contractor is still there, along with the scaffolding and metal subs. But now the roofing, siding, glazing, doors and windows, masonry and brick, and plastering subs are there as well, closing the building off to the elements.

Phase risks

By this stage, the risks begin to mount. Retainage, weather delays, bankruptcy, and materials pricing are still concerns, but schedule delays are also commonplace now.

Also, fund shortages from waiting for progress payments start to stretch construction companies a bit thin, and designers or project owners changing specs only worsens the issue.

5. MEP (Mechanical, Electrical, Plumbing)

With the building envelope sealed, specialty subs are able to get on the site and do their jobs.

The general contractor is still on-site and overseeing the project. Mechanical contractors can install boilers, air handlers, ductwork, and other equipment. Electricians can start installing panels, generators, switchgear, and distribution rooms, and pull wire throughout the building. Plumbers are also on-site, running water supply pipes as well as waste, drain, and vent pipes. This is also the stage where fire suppression and alarm subcontractors will start installing their systems, and elevator constructors can build their shafts and cars.

Phase risks

The only risk that fades a bit at this construction phase is weather delays, as the building should be weathertight.

Subcontractors are still feeling the effects of retainage and fund shortages, and they should still be worried about bankruptcies on the site. Materials pricing volatility is still a concern, and schedule delays and changing specs tend to add up.

Learn more: Understanding the Performance and Monitoring Phase of Construction

6. Finishes and fixtures

Of all the phases of construction, finishes and fixtures are the final push. At this point, the building starts to take its final form, inside and out.

There are many moving parts at this stage, and the general contractor has to stay on top of things to make sure it runs smoothly. The number of subs jumps tremendously: glazing, door and window, masonry, plastering, elevator, insulation, drywall, painting, tile, finish carpentry, and flooring subcontractors are all working inside the building to finish the job. Landscaping subs and swimming pool contractors might be working on buttoning up the exterior features. It’s a busy time for everyone involved.

Though it’s the final push, this phase isn’t any less risky. Communication issues over finishes, materials pricing, and changes in specs can cause massive scheduling delays. Retainage checks might be getting closer, but the strain of fund shortages and concern of bankruptcy are ever-present.

Closeout

Once the major stages of construction are in the bag, it comes time to wrap the job up. Usually, this is where a general contractor runs through the punch list of small items that still need squaring away. They may call subs back to the jobsite at this point to button up work that requires a specialty contractor’s attention.

Once the project meets substantial completion, final payments and retainage can go out to the individual contractors as well. This influx of cash allows the subs to float their next jobs and start the process over again.

How to manage financial risk in every construction phase

Most contractors float projects, which means they use their own money to buy materials and mobilize their projects. Their first opportunity to recover some of these costs is their first progress payment, which often can’t come soon enough.

When a contractor spends their own money to fund a job, they’re sacrificing their cash flow. Less cash flow makes growing the business a challenge. For smaller companies or companies looking to scale quickly, this is a significant issue.

For contractors and subs, getting paid during is notoriously challenging. Between the delays preventing the contractor from making progress, project owners dragging their feet on payment, or GCs holding onto payments as long as possible, it can take seemingly forever to get paid. That’s a real problem for a business fronting the money to start their portion of the project.

One way that contractors can protect their cash flow is by using materials financing. By avoiding over-extension on the materials for one project, they may be able to take on more projects and grow faster without relying on their cash.

Contractors can take many steps to get paid faster, and they are often most effective when followed simultaneously. One of the most effective ways to reduce financial risk and improve cash flow is by protecting their right to file a mechanics lien.

By sending notices early and paying attention to the project state’s deadlines, contractors improve communication on the job, and ensure they have lien rights — if and when they need them.